Even though India has major strengths in chip design and in making the software that actually commands the processors to execute specific tasks, chip-manufacturing has never been the country’s strength.

After almost fifty years, Moore’s Law - which set the pace for innovation in the world of computing and electronics - is faltering.

The tiny chips that housed ever-more transistors with every passing year, increasing processing speed, will no longer be able to do so.

Experts say this provides a huge opportunity for India, which missed positioning itself as a hub for semiconductor fabrication in the early days, when South Korea, China and Taiwan took the lead.

This was partly because fabs are capital-intensive and need fresh investments every three to five years just to address obsolescence.

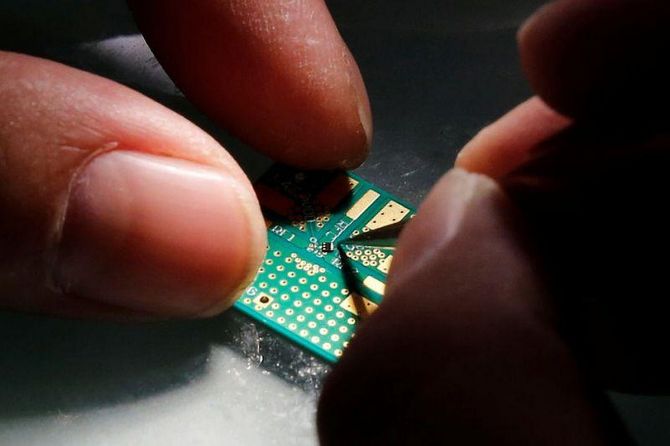

“Semiconductor chips are at the heart of everything around us,” says Vinod Dham, a leading Silicon Valley-based entrepreneur and venture capitalist, who is also known as the father of Pentium, the hugely successful microprocessor brand by Intel.

“As 50 years of the relentless march of Moore’s Law is coming to a halt, a level playing field for new entrants like India is opening up.”

Moore’s Law is based on the prediction made by Gorden Moore, co-founder and former head of leading chipmaker Intel back in 1965, that the number of transistors in a silicon chip will double every two years, increasing processing speed and bringing prices down, as more power is packed into the smaller chips, making chipsets more affordable.

This observation became the golden rule in the electronics industry, setting the pace for making smaller, faster and more affordable transistors, which have a raft of uses.

When a chip becomes smaller, the distance an electron has to travel reduces, thus increasing the speed of the chip.

Chips that used to be 28 and 25 nanometers a few years ago are now seven and even five nanometers, if one looks at the latest Apple processor chip.

A 5-nanometer chip is like two to three atoms going into the making of a transistor.

“We can’t go below that, because there is a physical limit to how tiny you can make it, after which the P-N junction won’t work,” says Srikanth Nadhamuni, co-founder and chief executive officer (CEO) of Khosla Labs, and part of the team that made Intel’s first Pentium processor.

A P-N junction is basically an interface between two types of semiconductor material which make the silicon transistor work.

“Below a certain level it can’t work, because there are physical limits to the way things work at the atomic level,” adds Nadhamuni.

Even though India has major strengths in chip design and in making the software that actually commands the processors to execute specific tasks, chip-manufacturing has never been the country’s strength.

One reason is that the setting up of semiconductor fabrication units or fabs requires huge investments, as the technology becomes obsolete every two years, requiring fresh capital injections to upgrade the fab and stay in the game.

Second, fabrication work is said to be only about 40 per cent of the total cost of a semiconductor chip.

“If Moore’s Law really slows down and stops, fabs will really become cheaper, because then you can amortise the cost over many years, which is a huge benefit for India.

"For example, if a 5-nanometer fab lasts for 10 years instead of three years, one will get enough time to monetise the investment,” says Lalitesh Katragadda, former Google India engineering head.

“Also, most of the action will move to software instead of hardware, (an area) where India has acquired significant strengths.”

While silicon chips can’t be further reduced in size, technologists worldwide are working on a slew of alternatives, including 3D stacking, parallelism and multicore chips.

In 3D stacking of chips, instead of chips being laid out on the board, they are placed on each other, which will continue increasing volume and speed.

They are also trying to break the problem into multiple cores and then combining the cores after solving the sub-parts (this is called parallel or distributed computing).

Placing multiple cores in the same CPU will give them the power of many CPUs, all on the same chip.

“While multicore chips is one of the alternatives to get faster processing, there is also a limit on how many cores you can put inside a chip,” says Kris Gopalakrishnan, co-founder and former CEO of Infosys, and also an angel investor.

“India can play a role there and on the fab side, you need to track the new materials and new technologies that are coming, and see whether you can take a lead there.”

Photograph: Kim Kyung-Hoon/Reuters

© 2025

© 2025